Finally, some progress, put in some leave this past week to start with all the repair sections on this bus.

All loaded up ready to take through to the factory, pretty unpleasant job loading it up as this past week’s weather here in the Cape was appalling.

Started off with repairing the driver’s door hinges, welded new plates in and attempted to remove the hinge pin as the hinges were completely seized. No luck even in a hydraulic press, so gave some good old heat treatment after which they finally budged.

Then it was to repair the upper hinge mount on the A-pillar, lower was no worries as it was completely being replaced, but the top one had all 4 bolts broken off as well as being rusted. I cut a slot to remove it and made a new one. Thought it would be easiest to make it out of some thick plate, cut it to correct size, drilled, tapped and managed to slide the new one in with ease.

While we’re on the driver’s door:

Test fitting the outer dog log with A-pillar repair section and inner front valance. It would have been ideal to actually replace the complete outer dogleg as there was some previous accident damage, but decided to leave it as it continued onto the front door and doesn't look so bad considering this ratty / rusty / patina way its going to remain in.

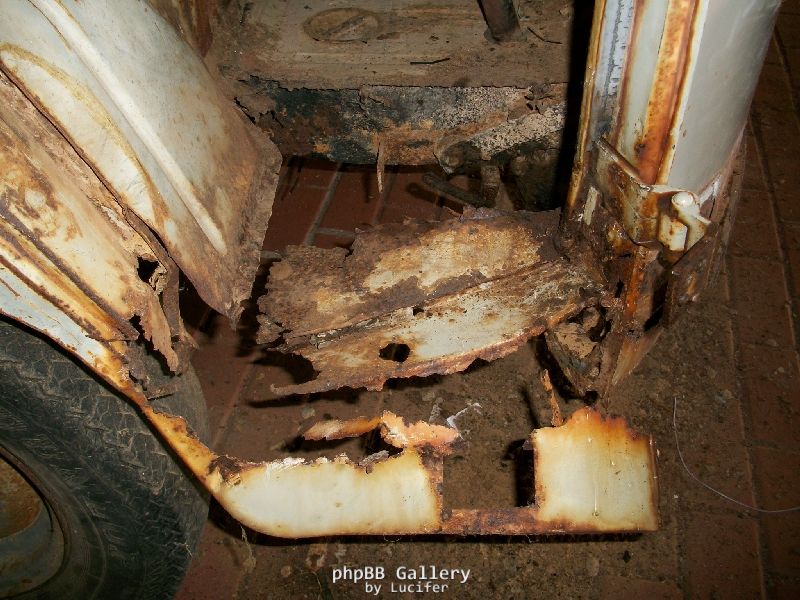

Floor repair section, A-pillar, inner & outer dog-leg all prepared for welding.

Inner front valance for test fitting, still need to fabricate some plates to join/repair the left A-pillar to the valance as I had to unfortunately remove parts of it due to some rust.

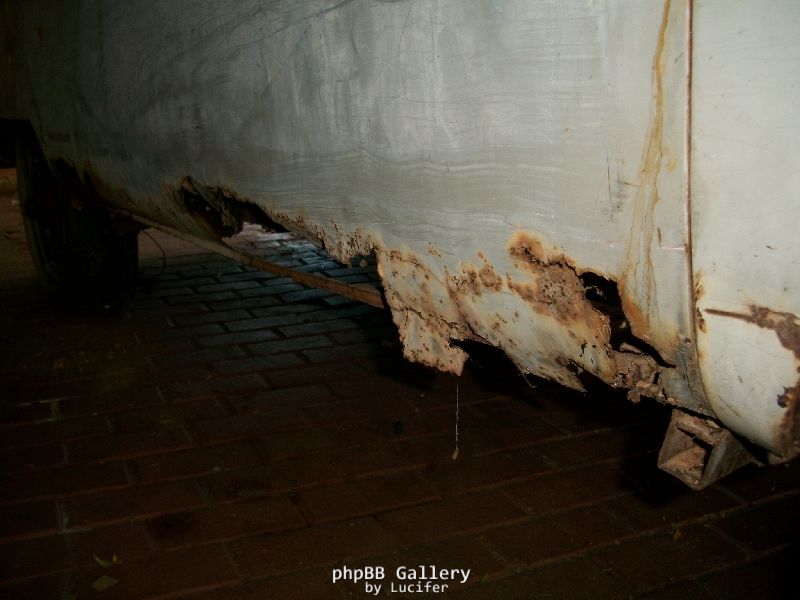

Test fitting left inner rocker, B-pillar repair section and outrigger.

Left side outer rocker, B-pillar and small sill repair section all fitted, now ready for final welding.

Long side support pillar repair sections welded in place.

As with the other side, I found it better to have some support for clamping and welding to have a backing plate behind the weld of these long sections, so I spot welded some sturdy plate onto the outer rockers before slotting into place.

Long side on for test fitting, unfortunately ran out of time today, will have to finish next weekend.

Overall I am quite happy with this week’s progress, but I am really happy with these repair panels, I just simply can’t explain how well these KlassicFab repair panels work, I cannot fault them, they really do fit perfectly. Many thanks to Splitbusaholic for the sections as well as making a turn this week to check out the progress and give some advice.

Other jobs while the bus is still on the lift:

I have to finish bending and installing the new tubes for the clutch and accelerator cables as the old ones are completely rusted.

Install new copper brake pipes

Complete all the finishing welding on the repair sections

Acquire lower nose repair section and jacking points from Splitbusaholic

Weld in front cross-member repair sections above jacking points

Decide on how to sort out the small sections of the floor I had to remove to gain access to rockers, perhaps floor repair sections are an option, but still deciding if I can make up something.

Will hopefully be able to post some more completed area's by next weekend...

dammit this bus is looking wicked already, have you worked out the colour, just love the whole thing, the story, the recovery, the whole tootie

dammit this bus is looking wicked already, have you worked out the colour, just love the whole thing, the story, the recovery, the whole tootie