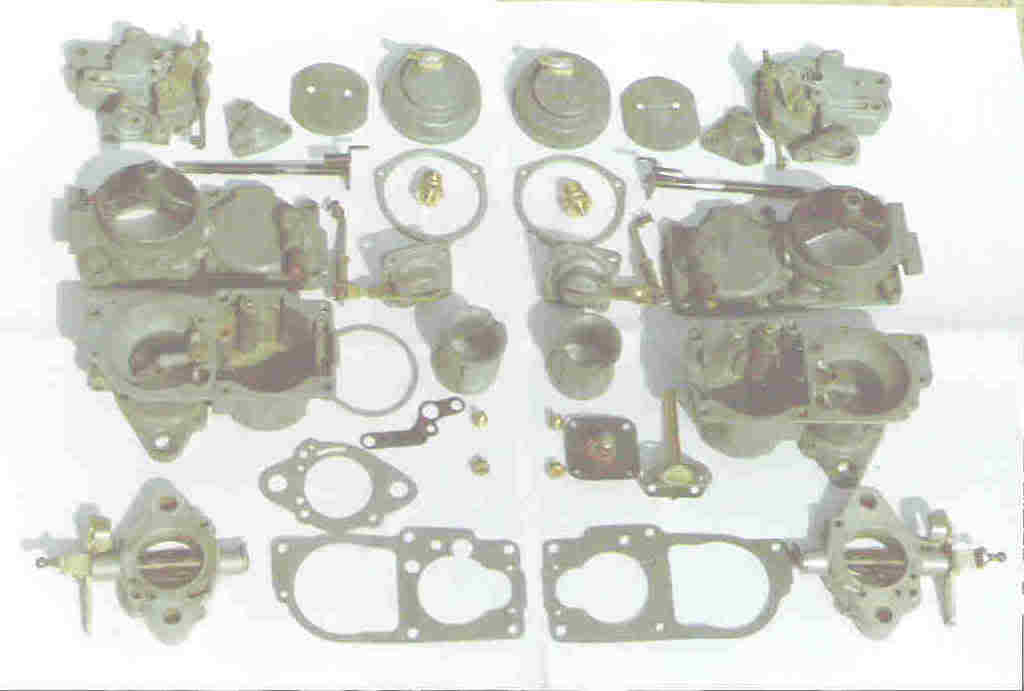

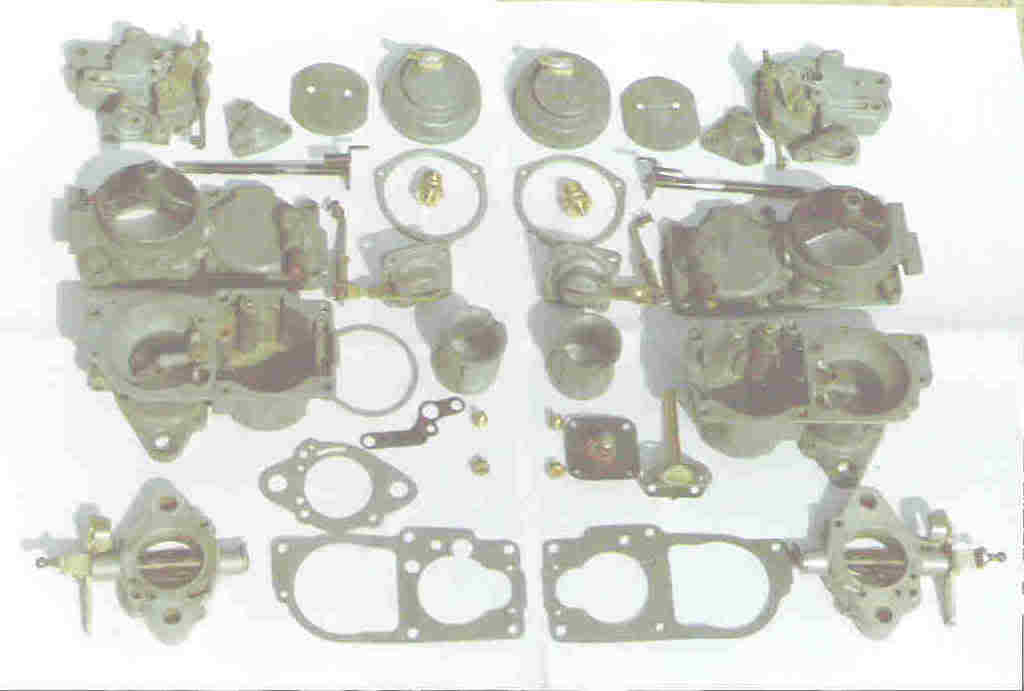

Photo shows Brazilian upper and lower carb castings,with German centre casting,(with the different emulsion tube).

Before each acceleration test,first drove the car for the engine to get hot. However,still had problems with inconsistent times.Accuracy was important for comparison purposes. The times were faster with a hot engine. Cylinder head temperature was going down while waiting for a clear road,sometimes had to wait long for a gap to do a test.

It turned out the engine was overcooled.The previous owner had removed the thermostat flaps. Installed the thermostat system and problem solved.By the way,found that it regulates at 120 deg celsius (Cyl. head temp) on my engine. At 130kmh it eventually sees 140deg,unless its very cold. Hottest ever was 160 deg,at 150kmh in 36deg weather. When entering 60kmh zone in a town after 130kmh on highway, flaps start to partly close,regulating heads to 120 deg. Found that flaps stay fully closed for first 9kms on highway. In town it takes up to 12 km before the start to regulate,(partly opening). Even though thermostat is marked 65 deg,it is not in direct contact with the head.

Believe some later south american beetles used a thermostat that opened at a higher temperature.Some late type 4 engines as well.In future may try one of them.

Must ad that all the cooling tin and seals are in place. Also used bottom cylinder cooling tin designed for the late US fuel injected type 3. Its use is controversial, and i see why. These are reproductions and they dont fit well. Took a few days of brazing pieces of plate onto them and filing with needle files. Like other late seventies engines,it had a slightly smaller crank pulley,so i fitted a bigger one from an early seventies model. In retrospect i dont think it was neccessary.

VDO cyl-head temp gauges usually read to 300deg cels. They use an uncompensated thermocouple that fits in place of the sparkplug washer. Complicates plug replacement,and they measure the difference between head temp(hot thermocouple junction) and the "cold junction" inside the gauge.

Wanted better accuracy.Found a VDO cyl-head gauge made for a Deutz diesel engine. It reads from 60 to 200 deg,so the scale is more spread out. Also easier to notice when its hot,needle closer to upper end. It uses a thermistor sensor similar to the oil temp sensor,just made for 200 deg instead of 150 deg. Not affected by temperature at the gauge. Tested sending units in boiling water while connected to gauge,they were accurate.

Mounting the sending units was difficult. Found a space at the bottom of the heads,in the middle close hetween the combustion chambers. That is a hot air area,sending unit is not affected by cold cooling air. Made adaptor blocks from aluminium. Had to be a perfect fit for proper heat conduction. Used Prussian Blue,(think that is wat it was called) to see where it made contact. Used a needle file and sandpaper.Took a few days to get a good fit. Used a grub screw to keep adapter in place. Used high-temp heatsink compound.

There is a sending unit in each head,with a switch under the dashboard.

Cyl head temp and oil temp is not directly related. Head temp changes quicker than oil temp. Head temp is more related to load,while oil temp is more affected by high rpm when there is more friction and wear. (Also have the vdo oil temp gauge).

Read the following in a US magazine:

During a test of different performance parts on an engine dyno,it was found that just adding high pressure valve springs, it lost a few hp,(which generated a few kilowatts of heat,resulting in higher oil temp.) That was a std 1600 with 1.4 to 1 ratio rockers.

Staying Aircooled is so much nicer.

Do'nt assume anything- (While doing fault-finding).